Problem statement

Polyethylene terephthalate (PET) is the world’s most abundant synthetic polyester and one of the most popular plastic types. Widely used in everyday products from plastic bottles to clothes and textiles, PET holds tremendous value in contemporary society through packaging and affordable clothing. However, with 70 million tonnes of PET used in textiles and packaging annually, accumulation of PET waste has become a serious environmental hazard, threatening aquatic ecosystems and taking up precious land space. Unfortunately, the same properties which makes PET a valuable asset– durability, pliability, hydrophobicity– makes it difficult to break down.Current methods of dealing with PET waste include landfilling, which is not very sustainable since Hong Kong’s landfills are running out of room and toxic secondary pollutants are released through the process. Besides, none of the plastic can be recovered to form new plastic. Mechanical and chemical processing of PET are also possible ways of recycling PET. However, mechanical recycling weakens the plastic over time due to the shredding process, while chemical recycling requires much energy and extreme conditions such as high temperatures and pressure, making this method restricted to well-equipped facilities. Also, biodegradation is becoming more common but its overall efficiency is low.

Solution and company description

Eco.ly is a self-sustaining bioreactor that aims to provide a cheap, efficient and non-polluting method of PET degradation. Instead of selling the bioreactor, we plan to have customers pay us to provide them with a plastic-offsetting service (e.g. companies who want to go plastic-neutral).2.1 How the product works

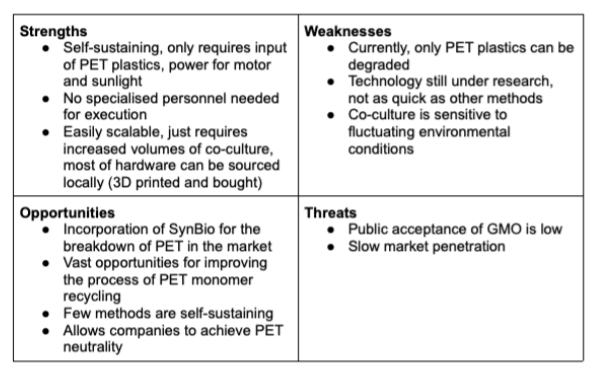

2.2 SWOT analysis

2.3 Business model

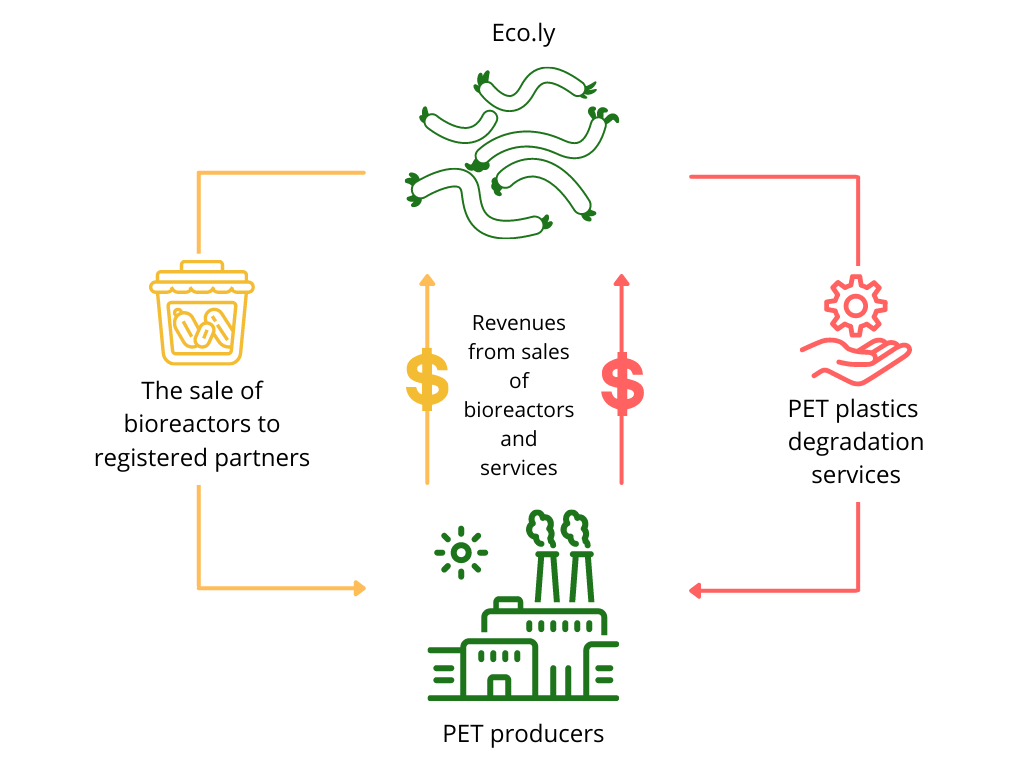

Our business model is based on:

- The sale of co-culture system directly to consumers in our targeted sectors (mentioned below)

- The sale of plastic-offsetting services

2.4 Impact

Although PET is damaging to the environment, it is unreasonable and impractical to totally halt its use. PET is a valuable asset to many, especially those in low-income areas, providing affordable clothing and a means of transporting food and water.

- Rethinking fast fashion and food packaging industries through monomer recycling

- Stopping PET plastic waste from entering the environment

On the other hand, microplastics – defined as particles of plastic less than 5 mm in diameter – have brought plastic pollution back into the forefront of public conversation. Microplastics typically interact with species at the base of the aquatic food chain, threatening the stability of aquatic ecosystems. Accumulation of microplastics and their associated toxins may then impact human food sources with the full effect on human consumption currently unknown. With Eco.ly, as the PET plastics are reused, they do not interact with the environment as much, reducing the amount of microplastic chip-off.

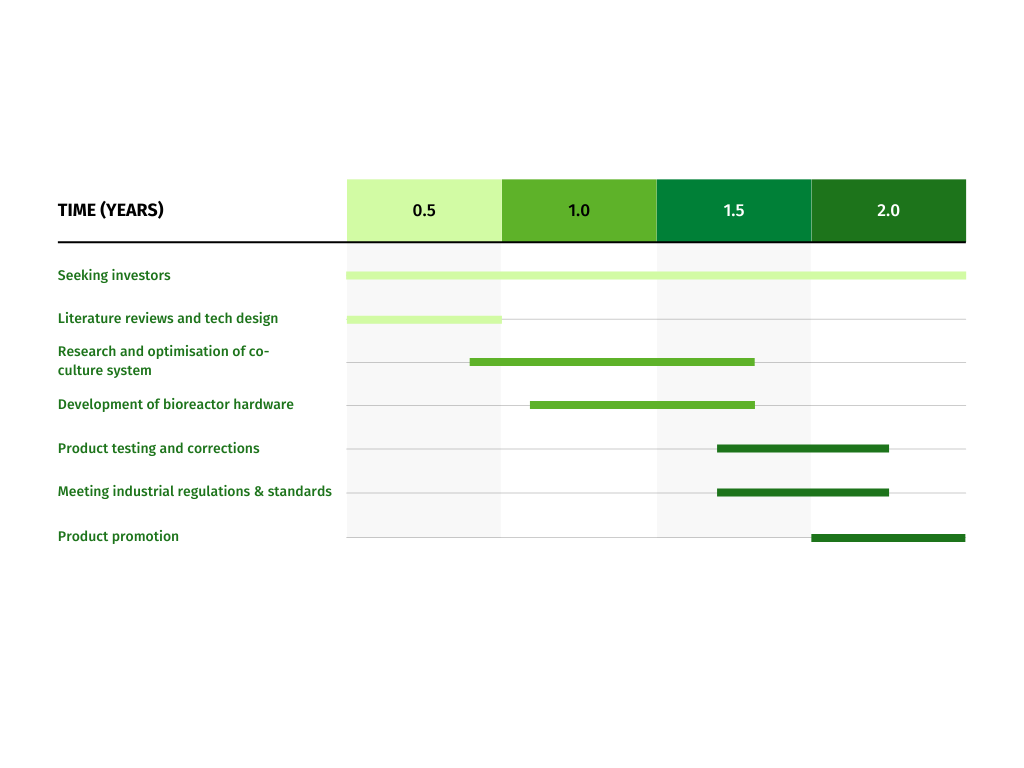

2.5 Timeline

- Clearbot

- Plastics recycling plants

- Sustainable fashion companies

Industry analysis

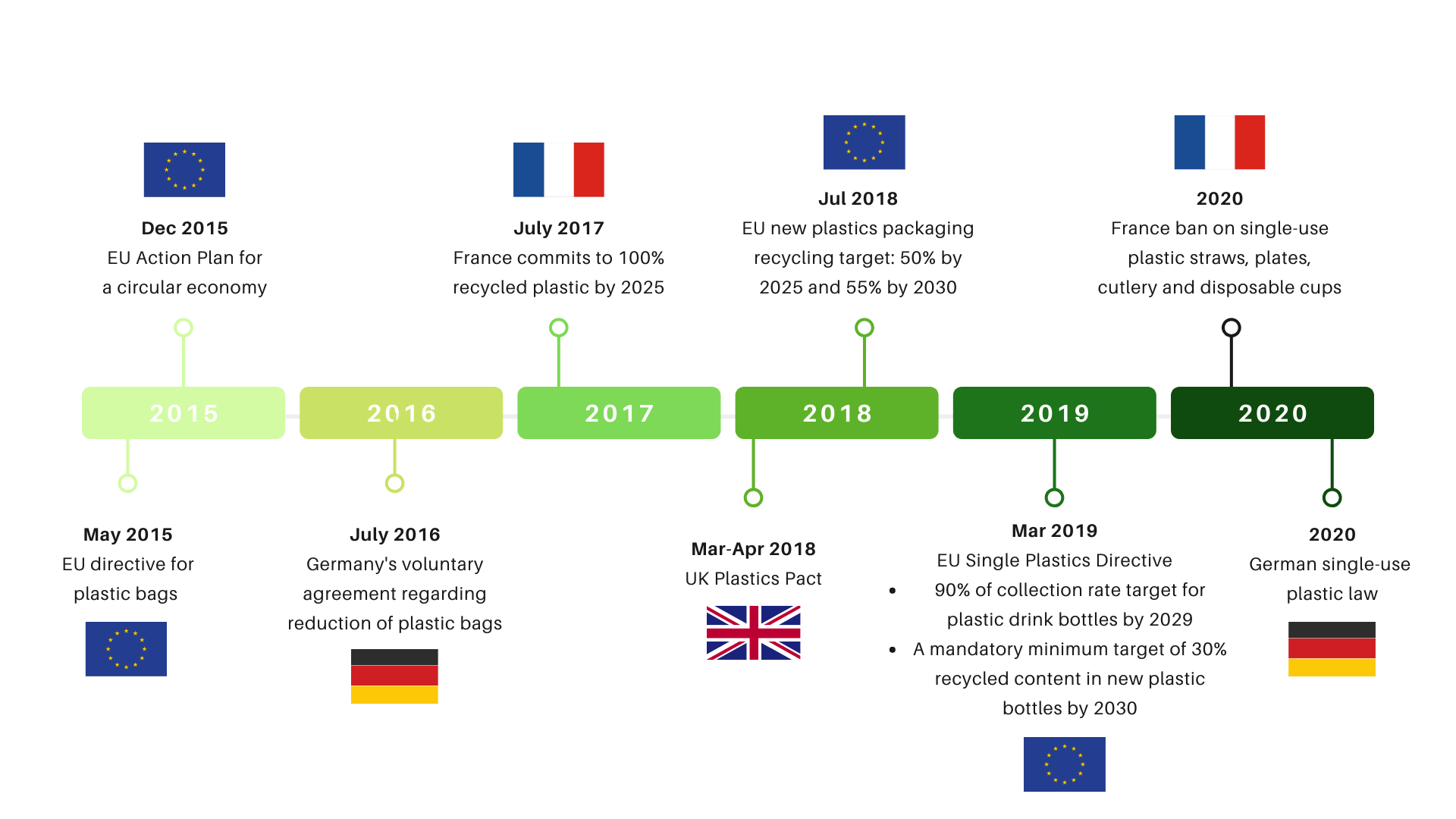

3.1 Growing regulatory pressures for plasticsWith plastic being linked to issues such as pollution and health, numerous international initiatives aimed at boosting the plastic recycling rate, thus the plastic recycling market, have been implemented in the last few years. Below is a non-exhaustive timeline of these initiatives.

In 2015, the Plastic Shopping Bag Charging Scheme was fully implemented in the entire retail sector where customers are charged a small fee should they need a plastic bag. In July 2021, a public consultation on Scheme on Regulation of Disposable Plastic Tableware was launched, in which it was proposed that the local sale and distribution of any plastic-containing tableware to customers, for dine-in and takeaway services, would be phased out starting 2025 [1]. Regrettably, the consultation paper also proposed the inclusion of plastic substitutes including biodegradable plastics, as it has been a term inaccurately claimed by many for the sole purpose of enticing customers [1].

3.2 Industry trends

In general, the global plastic recycling market is expected to reach USD 65.3 Billion by 2026, growing at a CAGR of 7.5% from USD 45.5 Billion in 2021 [2].

There is an establishment of new initiatives concerning the reduction of plastic waste, due to the increasing awareness about pollution, global warming and the consequences of excess plastic production and consumption. For this reason, more research and development has gone into investigating the feasibility of producing plastic alternatives, such as bioplastics, so as to reduce pollution thus maintaining environmental sustainability.

In 2016, the Monitoring of Solid Waste in Hong Kong found that 21% of Hong Kong’s municipal solid waste is plastic waste [3]. Not only that, PET is also one of the main constituents reaching our landfills; a whopping 8.3 million PET bottles are dumped every day [3]. What is even worse, only 13.9% of plastic waste is recovered for recycling [3]. Albeit the lack of waste segregation and recycling, especially for plastic waste, there is a massive opportunity for the recycling industry to fill in the gap by introducing new recycling technologies because current recycling practices are linked with an assortment of drawbacks as mentioned in Section 1.

Moreover, in terms of materials that can be recycled, PET is expected to be the fastest growing as the recycling process allows for it to become a material that can be re-used in various industries. After PET is recycled into PET flakes or monomers, they can be used to create new packaging materials, fibres for clothing and carpeting in the textile industry and so on.

Furthermore, the requirements of production and post-consumer management grow stringent over time, as illustrated in section 3.1 regarding the regulatory pressures for plastic, which would greatly contribute to the growth of the plastic recycling industry all over the globe.

3.3 Industry regulations

Eco.ly involves the use of genetically engineered microbes (GEMs), which is a more specific branch of genetically modified organisms (GMOs). It is apparent that it comes under the supervision of regulatory authorities in terms of its appropriate level, format of use and its applications.

One of the main regulatory bodies in charge of such guidelines is the United States Environmental Protection Agency (U.S. EPA). However, most of their regulations mostly apply to food substances that are produced using GMOs, where it is necessary to ensure that both the GMO and the food made from GMO is considered safe and non-toxic to eat.

Other than the U.S. EPA, there is also The Convention on Biological Diversity, which is the primary international forum that discusses the regulation of synthetic biology. Not to mention, some protocols apply to synthetic biology innovations. One good example is The Cartagena Protocol which applies to any kind of living organism that “possesses a novel combination of genetic material obtained using modern biotechnology” [4].

In Hong Kong, the Convention and Protocol has been in force since 9 May 2011 [5]. Additionally, the GMO (Control of Release) Ordinance Cap. 607 is also in force to control the release of GMOs into the environment, as well as its imports and exports [5]. Under this Ordinance, any kind of GMO release would need prior approval from the Agriculture, Fisheries and Conservation Department of Hong Kong [5]. Considering the lack of harsh regulations in Hong Kong, a sizable opportunity is expected for innovations based on synthetic biology concepts and techniques.

Market analysis

4.1 Target market selectionIn the beginning, we would not like to define our target market too broadly. As a small company with a limited amount of resources, targeting many different segments of the market increases the financial risk past a viable point. Initially, it is better to market Eco.ly to a smaller market, but doing it efficiently. As a result, Eco.ly will first target companies in Hong Kong who want to find an easy solution to degrade their PET wastes or who want to offset their PET plastics production. This can be done when the efficiency of the Eco.ly system has been optimised to degrade large amounts of PET plastics at any one time. As a result, Ecol.ly could replace other ways of PET recycling that are costly or produce harmful byproducts.

4.2 Target market size

In 2017, the global market for the production of PET bottles, packaging and films represented around 24 million tonnes with an annual growth rate of 3.4%. For PET fibers (textiles, rugs, carpets, pillows, duvets, etc.), production represented 42 million metric tons, up by 6% per year. These production levels could reach over 30 and 67 million tonnes respectively in 2025. (Sources: IHS Markit in 2018 and PCI Wood Mackenzie in 2018)

The largest– the plastic bottle industry, is estimated to produce an all-time high of approximately 583.3 billion PET bottles globally in 2021. With a total addressable market of HK$8.4 billion as the potential global market revenue and a serviceable available market of HK$2.2 billion as the potential local market revenue, Eco.ly will cater towards major industrial sectors with massive PET production. Focus will first be placed on Hong Kong’s disposable plastic container industries boasting a serviceable obtainable market of at least HK$300 million.

4.3 Competitor analysis

4.3.1 Direct competitors

- Companies who do PET plastic biodegradation

4.3.2 Indirect competitors

- Biodegradable plastics companies

- Companies that recycle plastics by mechanical or chemical means

Financial projection

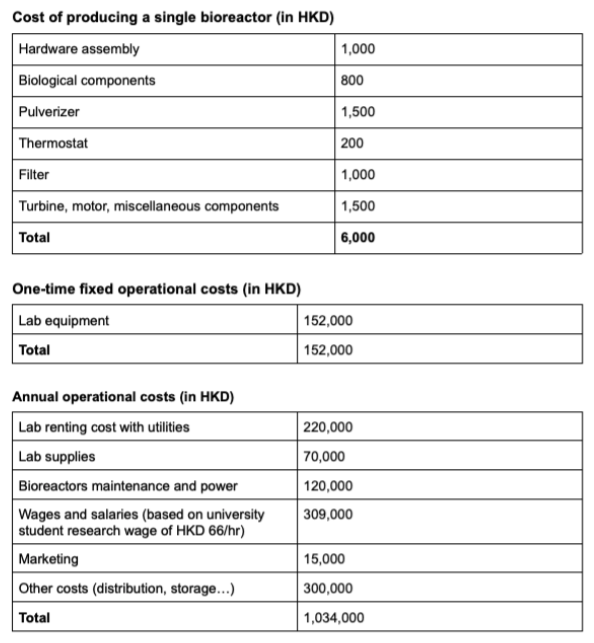

5.1 Costs

5.2 Funding

During the course of research and development, we came in touch with several funding bodies to cover the expenses of our project, e.g. Tam Wing Fan and Philomathia Foundation Innovation fund. They were really interested in our project and especially in its continuation. They are considering funding us for a maximum HKD 100,000 for a year to see through the development of Eco.ly.

Considering the great environmental and social impact that Eco.ly could meet, we have also applied for several funding competitions, one such being the iGEM Impact Grant where we won USD2500 on the basis of the impact Eco.ly could bring. The second was the Nan Fung Group’s Mills Fabrica Techstyle for Social Good Competition, an international competition where we competed with startups from around the world (e.g. Ghana, Hong Kong, United States etc.) as one of the 12 finalists. While we did not emerge as the winners, we were still able to gain valuable insights from the judges and other competitors regarding the direction of our project and potential technologies that could be incorporated.

Other than conventional funding streams, we also entered a collaboration with Koding Kingdom, a coding academy for children in Hong Kong, in which we agreed to teach bioinformatics summer camp courses (click here for further details) to help fund our research and project activities. It was agreed that the revenue from the camps would be split between Koding Kingdom and HKU iGEM. Additionally, HKU iGEM would solely be responsible for planning and delivery of classes, whereas Koding Kingdom would be in charge of marketing and student enrollment. Despite having done lesson preparations, we were faced with a lack of student enrollment. Unfortunately, due to this, our collaboration with Koding Kingdom prematurely ended and content was never delivered to the market in the summer

5.3 Pricing strategy

There are two main ways in which you can determine the price of your product: cost-based vs value-based. For Eco.ly, we have chosen cost-based pricing as it is more suited for an estimate at our early-stage. In order to check that our company is viable with the chosen price and generates enough profit, we made an estimate for our annual operational costs and costs of making one bioreactor, to produce a financial plan.

Due to existing competition, we could not set our initial costs too high as it would make market entry difficult. On the other hand, we also tried to resist the temptation to charge too low of a price, as while such a strategy would win a large market share, it would not be financially viable due to our up-front costs. Additionally, after feedback from judges from the Techstyle for Social Good competition and the Tam Wing Fan and Philomathia Foundation investors, customers make a price-quality attribution when looking at service/product prices. This means that they connect a high price with good quality and reliability. In the end, we decided to set the price of our bioreactor at HKD 18,000 per bioreactor or HKD 400 per kilogramme of PET plastic sent for biodegradation.

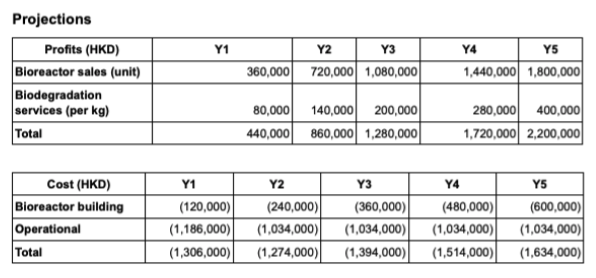

5.4 Projections

References

[1] Environmental Protection Department. (2021). [online] Scheme on Regulation of Disposable Plastic Tableware, Consultation Paper. Available at: https://www.rdpt.hk/en/consultation-paper/[2] Research and Markets (2021). Global Plastic Recycling Market Report 2021: Rise in the Demand for Plastics in Diverse Industry Practices. [online] GlobeNewswire by notified. Available at: https://www.globenewswire.com/en/news-release/2021/08/23/2284743/28124/en/Global-Plastic-Recycling-Market-Report-2021-Rise-in-the-Demand-for-Plastics-in-Diverse-Industry-Practices.html

[3] 地球之友 Friends of the Earth. (2016). [online] Plastics. Available at: https://www.foe.org.hk/en/Green%20Info/plastics

[4] Keiper, F. and Atanassova, A. (2020). Regulation of Synthetic Biology: Developments Under the Convention on Biological Diversity and Its Protocols. Frontiers in Bioengineering and Biotechnology, [online] 8. Available at: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7160928/

[5] Environmental Protection Department. (2011). Convention of Biological Diversity [online]. Available at: https://www.epd.gov.hk/epd/english/environmentinhk/conservation/policy/convention_bio_div.html [Accessed 20 Oct. 2021].